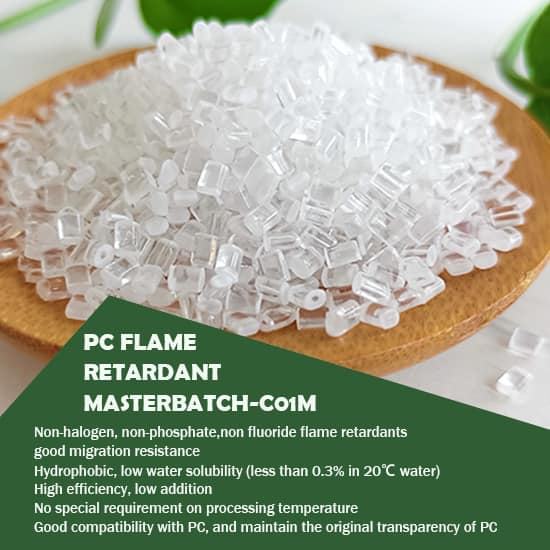

Flame retardant description

QIBOCHEM developed PC flame retardant without halogenated, and specialized for high transparent polycarbonate. The main component is organic acid salt without fluoride, It can be widely used to non-dripping PC FLAME RETARANT reach to UL94-V0, transparent PC flame retardant masterbatch, PC CF30 flame retardant masterbatches.

With different type of PC products, we recommend the dosage as below:

1. black/non-transparent sheets:

FCA107+antidripping 0.2%

C01+antidripping 0.2%

C02 + antidripping 0.2%

2.special solution for tinny thickness under 0.2mm :

FCA107+c01 (HIGHLY REQUIREMENT FOR THE HIGH TRANSPARENT)

c01+c02(TRANSPARENT WITHOUT HIGHLY REQUIREMENT)

Advantages:

1. fluoride-free, non-haloganated special sulfonate flame retardant

2. High-effective flame retardant

3. Less effective for the transparent of final products, apply into highly requirement of transparent

4. Good compatibility with PC, excellent comprehensive cost

Specification:

Item | Unit | PC | PC+3% flame retardant | PC+4% flame retardant |

Tensile strength | MPa | 70.2 | 70.2 | 69.9 |

Elongation at break | % | 230.3 | 228.5 | 226.2 |

IZOD Impact Strength | KJ/㎡ | 79.4 | 78.6 | 77.5 |

Flame retardant Level | 1.6mm | V2 | V1 | V0 |

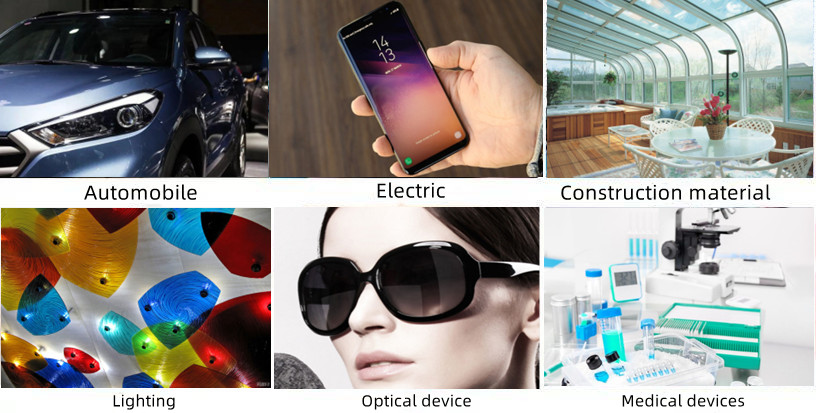

Application

PC sheet flame retardant, PC sheet flame retardant, PC film flame retardant, transparent PC flame retardant, transparent PC sheet flame retardant, polycarbonate flame retardant, polycarbonate sheet flame retardant, thin film flame retardant, transparent flame retardant,Phenyl silicone resin flame retardant,silicone flame retardant FCA-107,fluoride-free transparent PC halogen-free flame retardant

PDF DOWN

PDF DOWN