Application Range of PEEK

- Postdate: 2023-06-21

- From: qibochem.com

-

Application Range of PEEK

- Postdate: 2023-06-21

- Form: qibochem.com

-

PEEK —polyether ether ketone is a special engineering plastic with excellent properties such as high-temperature resistance, self-lubrication, easy processing, and high mechanical strength. It can be manufactured and processed into various mechanical parts, such as automotive gears, oil screens, and shift start plates, aircraft engine parts, automatic washing machine wheels, medical equipment parts, etc.

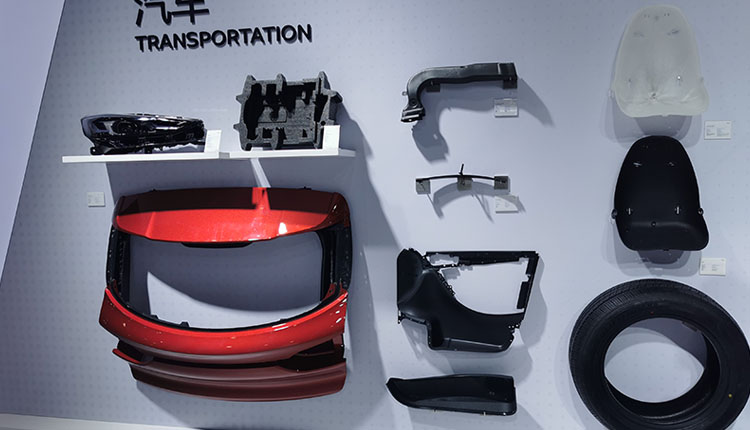

1. Transportation machinery such as automobiles

PEEK has excellent fatigue and chemical resistance properties, so it can be used in automotive fuel management systems. Due to its lightweight, it is replacing various active metal or aluminum components used in transmission, braking, and air-conditioning systems, including piston units, seals, gaskets, or bearings, which can significantly reduce vehicle weight and noise.

The growth of PEEK resin in the European market is particularly rapid in the auto parts market, especially the parts around the engine, transmission parts, and steering parts. PEEK plastics are used to replace some traditional high-priced metals as manufacturing materials. As the automotive industry adapts to miniaturization, lightweight, and cost-reduction requirements, the demand for PEEK resin will continue to grow.

2. IT manufacturing field

Semiconductor manufacturing and electronic and electrical industries are expected to become another growth point for the application of PEEK resin. In the semiconductor industry, in order to achieve high functionality and low cost, silicon wafers are required to be larger in size and more advanced in manufacturing technology. Low dust, low gas emission, low ion dissolution, and low water absorption are requirements for various equipment materials in the semiconductor manufacturing process. Special requirements, this will be the place where PEEK resin will show its talents.

3. The field of office machinery parts

For the separation claws of copiers, special heat-resistant bearings, chains, gears, etc., when PEEK resin is used instead of metal as their material, the parts can be lightweight, fatigue-resistant, and can achieve oil-free lubrication.

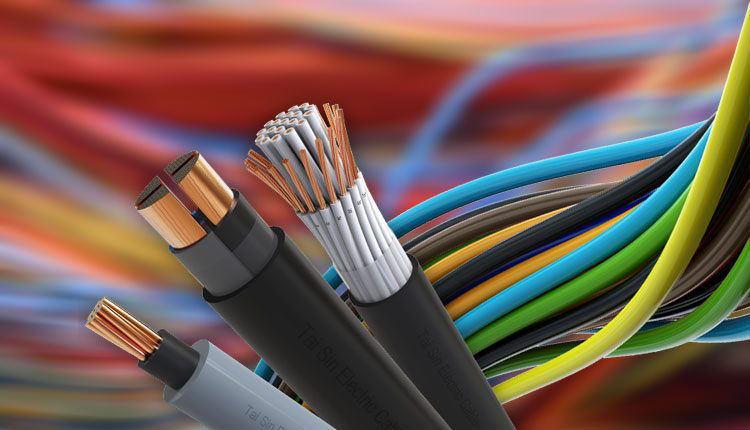

4. Field of wire coating

The PEEK coating layer has good flame retardancy, and its flame retardancy level can reach UL94 V-0 level without adding people and flame retardants. PEEK resin also has the advantages of peel resistance and radiation resistance (109 rad), so it is used in special wires in military and nuclear energy and other related fields.

5. Plates, bars, and other fields

In the process of applying PEEK in some special fields, it often encounters the phenomenon of small quantity and many varieties. At this time, it is very beneficial to use rods, plates, and other profiles for machining and manufacturing.

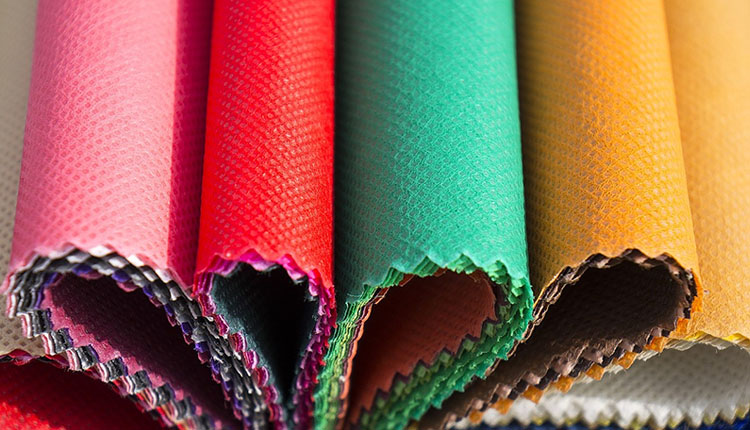

6. Fiber field

PEEK fiber (including monofilament) industrial filter cloth, industrial brush, and other products. In the field of composite materials, the charm of PEEK fiber lies in its thermoplasticity and high-temperature resistance. In addition to heat resistance, the attractiveness of industrial filter cloths and industrial brushes lies in their chemical resistance and abrasion resistance.

7. The field of medical analysis equipment

In the medical field, PEEK provides economical and innovative parts with excellent wear resistance, heat resistance, electrical resistance, and chemical resistance. Its applications in the healthcare field mainly include dental instruments, endoscopes, dialyzers, etc., and are mainly used in orthopedics.

Because PEEK can withstand repeated autoclaving, it can be used in the manufacture of endoscope parts, dental descaling devices, etc. in medical devices. In addition, due to the high strength and low dissolution of PEEK, it has been used in liquid chromatography columns, tubes, auxiliary files, etc. for instrumental analysis. Moreover, because PEEK has good compatibility with the human body, it has successfully replaced traditional titanium metal as an artificial bone material.

8. Aerospace

8. Aerospace

The aerospace industry requires safe and reliable materials. PEEK maintains its outstanding material properties even when exposed to high temperatures and corrosive fuels. In addition, PEEK's fluoroplastic has a low coefficient of friction and is suitable for processing in narrow spaces.

PEEK parts are widely used in the aerospace sector, for exterior parts because of their excellent resistance to rain erosion, and internal to reduce the risk of fire due to their low emissions of smoke and toxic gases, and have good flame retardancy.

Overall, PEEK is replacing an increasing number of aluminum and metal parts in aircraft. Such as clips, high-pressure hoses or wire conduits, etc. This saves up to 70% in weight and drastically reduces fuel costs.

9. Electrical Engineering

The excellent electrical properties of PEEK make it an ideal insulator. With excellent thermal properties, PEEK polymer parts can withstand high temperatures that traditional insulators cannot. These advantages, together with its long-term reliability, and temperature, pressure, and frequency durability, make it suitable for subsea environmental control equipment or connector pins for high-pressure water pumps.

Additionally, PEEK is being used in mobile devices. People's pursuit of thinner, lighter, and smarter mobile devices makes components based on PEEK materials very useful.

Shijiazhuang Qibo Chemical Co., Ltd. not only provides PEEK granules, but also can provide granules of various colors. Besides, we also provide PP, PC, PE, PA, PET, ABS, PVC, XPS, EPP, EPE, PEEK, PPR, PPA, PEI, PAI, LDPE, HDPE, DBDPE, DBDPO, BDDP, TBPC, ATO, TBBP flame retardants.