Comparison between Liquid and Powder Flame Retardants for Polyurethane (PU)

- Postdate: 2023-08-18

- From: qibochem.com

-

Comparison between Liquid and Powder Flame Retardants for Polyurethane (PU)

- Postdate: 2023-08-18

- Form: qibochem.com

-

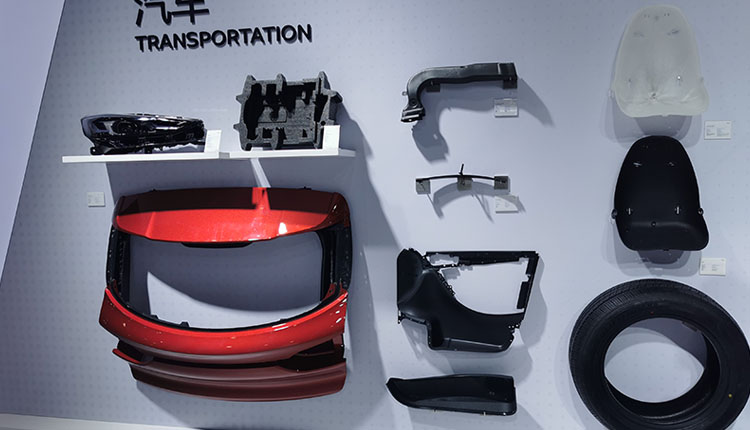

Polyurethane (PU) materials are widely used for their excellent properties, such as abrasion resistance, chemical resistance, and high strength. However, PU materials are prone to combustion when exposed to flames, which necessitates the incorporation of flame retardants to enhance their fire-resistant properties. PU flame retardants are available in two primary forms: liquid and powder. This article aims to outline the differences between liquid and powder flame retardants for PU.

Physical Characteristics:

Liquid Flame Retardants for PU: These are typically in liquid form and can be easily mixed with PU raw materials. They can be uniformly dispersed within the PU material and are suitable for processes like coating and impregnation.

Powder Flame Retardants for PU: These are generally in solid powder form and require thorough mixing with PU powder or particles during the manufacturing process. They are processed with the PU powder to create the final product.

Application Methods:

Liquid Flame Retardants for PU: Their liquid form allows for straightforward mixing with PU raw materials, making them suitable for applications involving coating or impregnation.

Powder Flame Retardants for PU: Powder flame retardants need to be blended with PU powder or particles early in the manufacturing process. They are better suited for applications where a uniform dispersion of the flame retardant is necessary.

Mechanism of Flame Retardation:

Liquid Flame Retardants for PU: These typically form a protective layer or gas phase barrier on the material's surface to slow down combustion.

Powder Flame Retardants for PU: Powder flame retardants often work through chemical reactions that generate inert gases or solidifying agents, hindering flame propagation.

Uniformity:

Liquid Flame Retardants for PU: Due to their liquid nature, achieving uniform dispersion in PU materials is relatively straightforward, reducing the risk of performance variability.

Powder Flame Retardants for PU: Ensuring thorough mixing of powder flame retardants with PU powder is critical to avoiding inconsistent flame retardant effects in localized areas.

In selecting the appropriate form of flame retardant, factors such as the application's requirements, processing methods, and material characteristics need to be considered. Regardless of whether liquid or powder flame retardants are chosen, thorough testing and experimentation are essential to ensure that the final PU products meet the necessary fire resistance standards.

Shijiazhuang Qibo Technology Co.,Ltd, located in Hebei China, a manufacture of PP, PC, PE, PA, PET, ABS, PVC, XPS, EPP, EPE, PEEK, PPR, PPA, PEI, PAI, LDPE, HDPE, DBDPE, DBDPO, BDDP, TBPC, ATO, TBBP flame retardants. We can provide UL94 /ROHS standard Functional Masterbatch, formulations of flame retardants, and even customize flame retardants. We can also provide additives for plastics, color masterbatch and raw materials.