Differences Between IXPE and XPE Foam Materials

- Postdate: 2023-08-11

- From: qibochem.com

-

Differences Between IXPE and XPE Foam Materials

- Postdate: 2023-08-11

- Form: qibochem.com

-

Introduction:

IXPE (Irradiation Cross-linked Polyethylene Foam) and XPE (Cross-linked Polyethylene Foam) are both high-performance foam materials widely used in various industries. While they share some similarities, they also exhibit distinct characteristics that make them suitable for different applications. This article aims to shed light on the differences between these two foam materials.

IXPE: Irradiation Cross-linked Polyethylene Foam

IXPE foam is produced by cross-linking polyethylene through an irradiation process. This results in a foam material with enhanced strength, durability, and a closed-cell structure. The cross-linking process involves using high-energy electron beams to create a network of interconnected polymer chains within the foam.

Key Characteristics of IXPE:

Enhanced Strength: The irradiation process imparts greater strength to IXPE foam, making it suitable for applications requiring high load-bearing capabilities.

Improved Thermal Stability: IXPE exhibits better resistance to heat, which makes it suitable for use in thermal insulation applications.

Water Resistance: The closed-cell structure of IXPE foam minimizes water absorption, making it ideal for applications where moisture resistance is important.

Excellent Chemical Resistance: IXPE foam is resistant to a wide range of chemicals, enhancing its durability and longevity.

XPE: Cross-linked Polyethylene Foam![]()

XPE foam is created through cross-linking polyethylene using either chemical or heat processes. This foam material possesses a similar closed-cell structure as IXPE foam but may have different characteristics based on the cross-linking method used.

Key Characteristics of XPE:

Versatility: XPE foam is available in various densities and thicknesses, making it adaptable to a wide range of applications.

Cushioning and Shock Absorption: XPE foam's cushioning and shock-absorbing properties make it suitable for packaging, sports equipment, and protective gear.

Thermal Insulation: XPE foam's closed-cell structure contributes to its insulating properties, which are beneficial in applications requiring temperature regulation.

Flexibility: XPE foam is known for its flexibility, making it easy to mold and shape for different applications.

Differences between IXPE and XPE:

Production Process: IXPE is produced through an irradiation process, while XPE can be produced through chemical or heat cross-linking methods.

Strength and Load-Bearing Capacity: IXPE generally offers higher strength and load-bearing capabilities compared to XPE foam.

Thermal Properties: IXPE foam exhibits better thermal stability, while XPE foam is also known for its insulating properties but may vary based on density and formulation.

Versatility: XPE foam offers more versatility in terms of available densities and applications due to its production methods.

Conclusion:

IXPE and XPE foams are both valuable materials with unique characteristics that suit various applications. IXPE excels in areas requiring strength, thermal stability, and chemical resistance, while XPE stands out for its versatility, cushioning properties, and flexibility. Understanding the differences between these two foam materials enables industries to make informed choices for their specific needs.

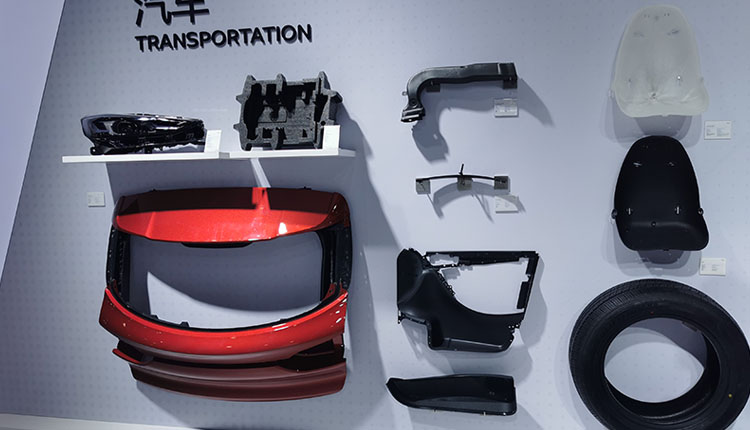

Shijiazhuang Qibo Co.Ltd., a manufacture of PP, PC, PE, PA, PET, ABS, PVC, XPS, EPP, EPE, PEEK, PPR, PPA, PEI, PAI, LDPE, HDPE, DBDPE, DBDPO, BDDP, TBPC, ATO, TBBP flame retardants. We can provide UL94 /ROHS standard Functional Masterbatch, formulations of flame retardants, and even customize flame retardants. We can also provide additives for plastics, color masterbatch and raw materials.