PEEK—Thermoplastic Super Engineering Plastics

- Postdate: 2023-06-01

- From: qibochem.com

-

PEEK—Thermoplastic Super Engineering Plastics

- Postdate: 2023-06-01

- Form: qibochem.com

-

1 Introduction

PEEK is an abbreviation for a resin called Poly Ether Ether Ketone, is one of the thermoplastic super engineering plastics.It is a material with particularly high performance among resin materials, and exhibits high functionality in many environments.In addition, PEEK is a resin that corresponds to the super engineering plastics (super engineering plastics) of thermoplastic resins, and is treated as a typical resin among super engineering plastics.

Super engineering plastics have improved heat resistance and mechanical strength for industrial use, but PEEK has particularly excellent heat resistance and chemical resistance.

2 Advantages and Disadvantages of PEEK

2.1 Advantages

2.1.1 Heat resistance, high temperature resistance, hydrolysis resistance.

Among super engineering plastics, PEEK is a material with excellent heat resistance, high temperature resistance, and hydrolysis resistance. The continuous use temperature is about 250°C, and it is also resistant to heat deterioration.

It also has excellent hot water resistance and can be used continuously even in steam at 200-250°C. Therefore, steam sterilization is also possible, and it has the performance to withstand high temperatures of 300°C for a short time.

2.1.2 Chemical resistance

PEEK has very good chemical resistance. It is a plastic that is resistant to many acids, alkalis, and organic solvents, and can withstand high temperatures. However, please note that it cannot withstand strong acids such as concentrated sulfuric acid.

2.1.3 Mechanical properties, creep properties, wear resistance

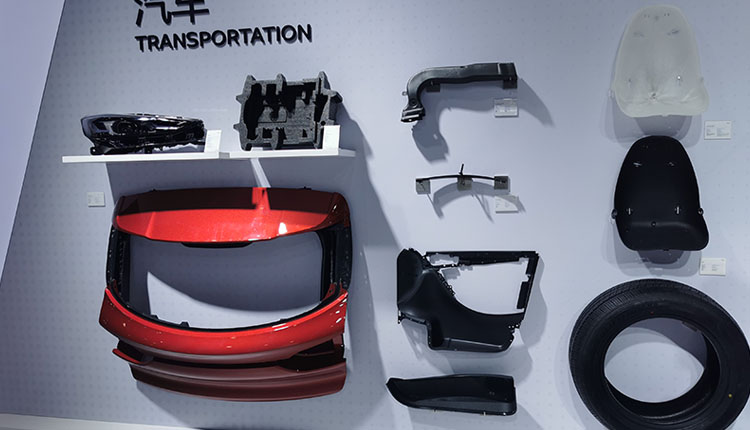

PEEK is a plastic that exhibits high strength and stiffness over a wide temperature range and has excellent mechanical properties. Strength is further enhanced by glass fiber and carbon fiber. It also has excellent creep properties and wear resistance, and is used as a substitute for metal.

2.1.4 Radiation resistance

General resins with thermal processability have the characteristic of becoming brittle due to the effects of electromagnetic waves and radiation. However, PEEK has a stable chemical structure, so it can be used in environments with electromagnetic waves and radiation.

2.1.5 Flame resistance

Since PEEK is a flame-retardant material, it is less likely to burn due to heat from friction than other plastics. It also has the advantage of generating very little smoke, corrosive gas, or toxic gas during combustion.

2.2 Disadvantages—high cost

PEEK has a wealth of benefits, but its cost is higher than other plastics.

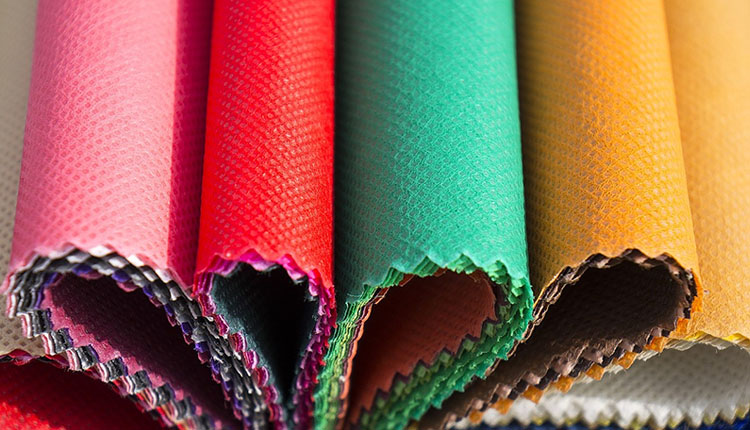

Shijiazhuang Qibo Chemical Co., Ltd. specializes in the production of PP, PC, PE, PA, PET, ABS, PVC, XPS, EPP, EPE, PEEK, PPR, PPA, PEI, PAI, LDPE, HDPE, DBDPE, DBDPO, BDDP, TBPC, ATO, TBBP flame retardants for 16 years in China.We have all kinds of PEEK granule,like pure white,red,blue,yellow,etc.We can meet your needs for different colors.We can also provide PEEK powder for 100 mesh,200 mesh,500 mesh and 600 mesh.