The Differences between PP Copolymerization and Homopolymerization

- Postdate: 2023-02-28

- From: qibochem.com

-

The Differences between PP Copolymerization and Homopolymerization

- Postdate: 2023-02-28

- Form: qibochem.com

-

1 The same points of PP copolymerization and homopolymerization

1.1 Both PP copolymer and homopolymer have very low water vapor permeability.

1.2 Moisture resistance, acid and alkali corrosion resistance, solubility resistance, poor oxidation resistance at high temperature, etc. It has no resistance to aromatic hydrocarbon (such as benzene) solvents, chlorinated hydrocarbons (carbon tetrachloride) solvents, etc.

2 The difference between PP copolymerization and homopolymerization

2.1 Copolymerization is changed to PP, which has synthetic rubber components, and the wires pulled apart by fire are flat and not long. However, after burning the homopolymerized PP, the wire will be long and round.

2.2 Homopolymer PP has disadvantages such as poor toughness, poor dimensional stability and easy aging, which limits its scope of application.

The copolymerized PP has the advantages of low heat distortion temperature, low transparency, low gloss, high strength, high rigidity, good heat resistance, good dimensional stability, good processability and excellent low temperature toughness, so it can be widely used It is used in the production of turnover boxes, bottles, di paint buckets, large containers and heavy-duty packaging, etc. It can also be used in the production of pipes, plates, battery shells, etc., and can also be used as the base material for other high-grade polypropylene special materials.

2.3 The flow rate MFR of PP ranges from 1-40. PP materials with low MFR have better impact resistance but lower elongation strength. For materials with the same MFR, the strength of the copolymer type is higher than that of the homopolymer type.

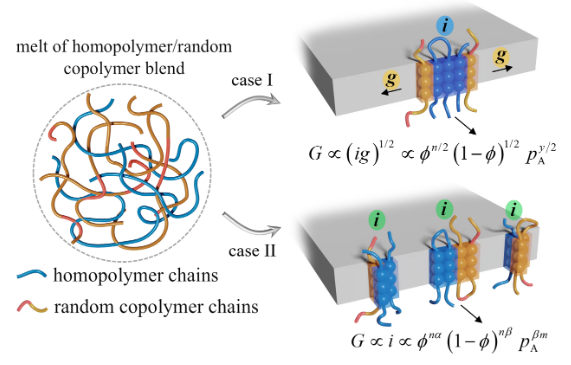

2.4 Physical properties: Generally speaking, random PP copolymers have better flexibility and lower rigidity than PP homopolymers. They retain moderate impact strength down to 32 degrees, and have limited usefulness when temperatures drop to -4 degrees.

2.5 The flexural modulus of the copolymer is in the range of 483 ~ 1034MPa, while that of the homopolymer is in the range of 1034 ~ 1379MPa. The molecular weight of PP copolymer material has less effect on rigidity than that of PP homopolymer.

Shijiazhuang Qibo Chemical Co., Ltd. has special PP environmental flame retardant QB-H01 for homopolymerization, QB-T03 halogen-free PP flame retardant (suitable for homopolymerization PP or copolymerization PP halogen-free flame retardant) and copolymerization PP flame retardant masterbatch QB -PN3 etc.