The Importance of Anti-Static Masterbatches in Nonwoven Fabrics

- Postdate: 2023-09-12

- From: qibochem.com

-

The Importance of Anti-Static Masterbatches in Nonwoven Fabrics

- Postdate: 2023-09-12

- Form: qibochem.com

-

Introduction:

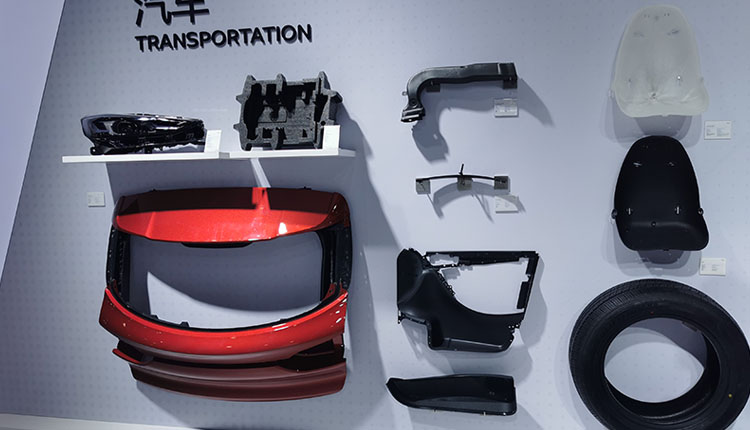

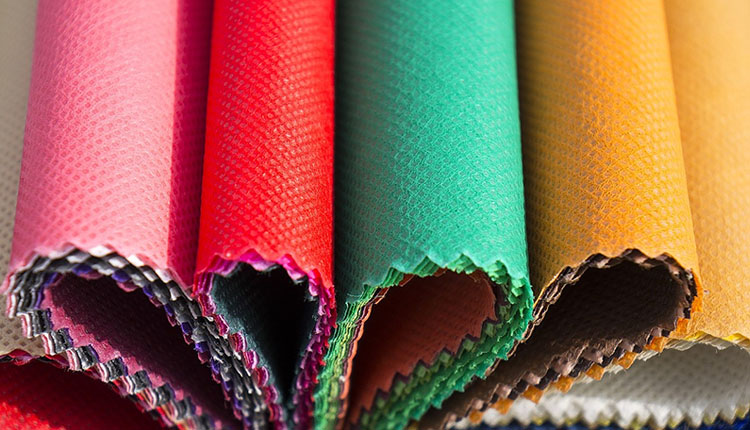

Nonwoven fabrics have become an integral part of various industries, finding applications in healthcare, agriculture, automotive, and more. These fabrics are popular due to their versatility, lightweight nature, and cost-effectiveness. However, they often face the challenge of static electricity buildup, which can have detrimental effects on their performance and usability. To address this issue, the incorporation of anti-static masterbatches has become a common practice. In this article, we will explore the reasons behind the addition of anti-static masterbatches in nonwoven fabrics.

Understanding Static Electricity:

Static electricity is the imbalance of electric charges on the surface of a material. It occurs when there is friction or separation between two surfaces, leading to the transfer of electrons. Nonwoven fabrics, being made of synthetic fibers, are particularly prone to static buildup due to their insulating properties. This static electricity can attract dust, dirt, and other particles, compromising the fabric's cleanliness and functionality.

Challenges Posed by Static Electricity:

1. Contamination: Static electricity can attract and hold particulate matter, leading to contamination of the fabric's surface. In industries like healthcare and cleanrooms, contamination is a critical concern.

2. Reduced Comfort: In applications involving clothing or medical textiles, static electricity can cause discomfort and irritation to the wearer.

3. Fire Hazard: Static discharge can ignite flammable materials, posing a fire hazard, especially in industrial settings.

4. Performance Issues: In automated processes, such as packaging and sorting, static-charged nonwoven materials can stick together or to machinery, leading to production delays and inefficiencies.

together or to machinery, leading to production delays and inefficiencies.

The Role of Anti-Static Masterbatches:

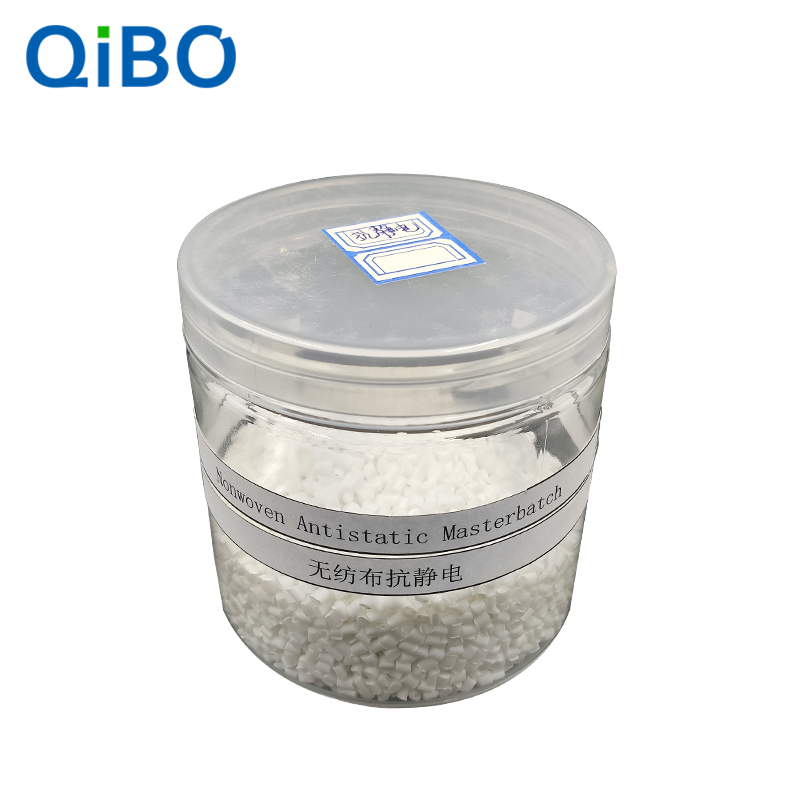

Anti-static masterbatches are specialized additives incorporated into the nonwoven fabric manufacturing process. These masterbatches contain conductive materials, such as carbon black or metallic compounds, which help dissipate static charges. Here are some key benefits of using anti-static masterbatches:

1. Static Charge Dissipation: Anti-static masterbatches provide a controlled path for the dissipation of static charges, reducing the risk of sparks and shocks.

2. Cleanliness: By preventing the accumulation of dust and dirt, these masterbatches help maintain the cleanliness and hygiene of nonwoven fabrics, making them suitable for critical environments.

3. Safety: In environments where flammability is a concern, anti-static additives can reduce the risk of ignition caused by static discharge.

4. Process Efficiency: Anti-static properties ensure that nonwoven fabrics do not stick together during production processes, thus improving manufacturing efficiency.

Conclusion:

The addition of anti-static masterbatches is a crucial step in enhancing the performance and usability of nonwoven fabrics. By addressing the challenges posed by static electricity, these masterbatches ensure that nonwoven materials remain clean, safe, and suitable for a wide range of applications. As the demand for nonwoven fabrics continues to grow, the importance of anti-static additives in maintaining product quality and safety cannot be overstated.

Qibo Technology Co., Ltd. not only has non-woven antistatic masterbatches, but also hydrophilic , anti-UV, and anti-aging masterbatches. If required, we also provide non-woven halogen-free transparent flame retardant masterbatch.