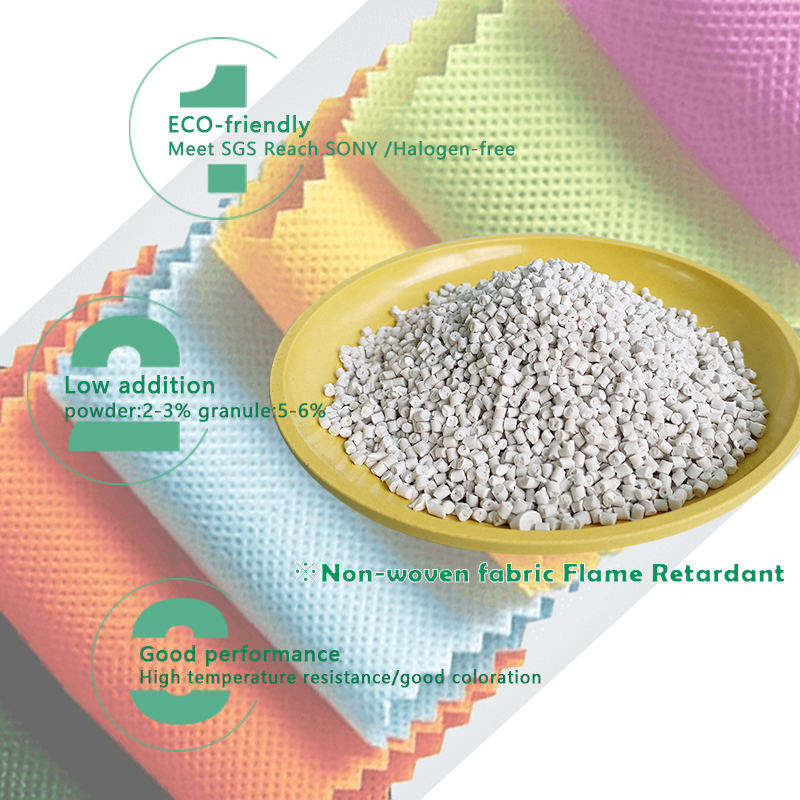

Flame retardant description:

1. Mainly contents with bromine.

2. Easy to use, mix directly with pp raw material uniformly.

3. One kind of flame retardants additive widely use in PE components.

Flame property

UL94-V2

Features

polymer activation treatment, compatibility, dispersity, weather resistance and other excellent performance.

High whiteness, no impact on the color and other properties of products.

Strong UV resistance, high temperature resistance with anti-block performance.

Environmentally bromined flame retardant, non-toxic with low smoke.

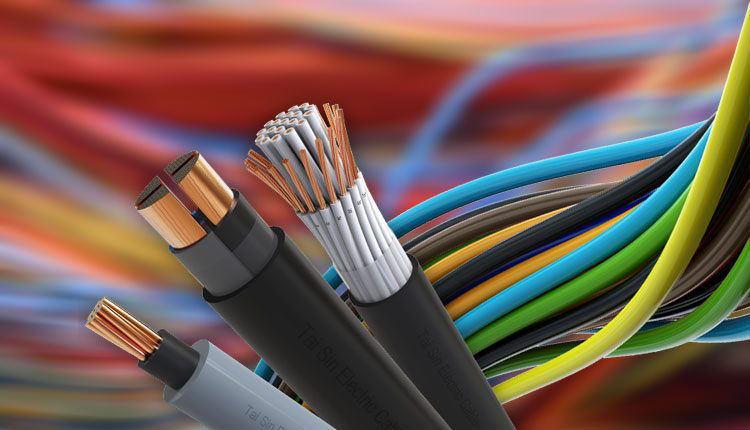

Application

PE flame retardant pipe, threading pipe, heat shrinkable pipe, PE bellows, bus bellows

Specification

Model | General flame retardant | Remarks |

Appearance | White slice granules | 1. Test with dosage of 18%,exact dosage based on the flame retardant requirement, 2. The dosage related with the thickness of products.

|

Content of flame retardant% | ≥85 | |

Melting temperature℃ | 130 | |

Decomposition temperature℃ | ≥300 | |

Recommend addition % | 18% | |

Reference standard | UL94 |

PDF DOWN

PDF DOWN